Postcard from the half-day seminar Digital Retrofit 4.0 at Swissmem in Zurich

Picture: Pascal Blanc, Head of Innovation at Industrie 2025 (left in picture) and Marc Tesch, CEO of LeanBI (right in picture).

Picture: Marc Tesch presenting the findings from the groups.

What added value does a digital retrofit offer you for your plant?

One of many questions we discussed together with you on November 24 in the half-day seminar “Digital Retrofit – Why and How to retrofit and convert your plants for the digital future” at Swissmem in the Industrie 2025 format.

We thank you for your time, your keen interest and the inspiring exchange with you!

LeanBI in the media on the topic:

Read the article on how LeanBI optimizes overall equipment effectiveness with data analytics solutions. Industrial companies do not necessarily need modern machines with built-in sensors for this. Their legacy systems can be retrofitted with suitable sensors.

Der Maschinenbau: Mit digitalem Retrofit zu besserer Overall Equipment Effectiveness

Iavcworld.de: Digitaler Retrofit befeuert die Effektivität von Anlagen

LeanBI in the media on the topic:

How can companies achieve cost savings by a factor of 10 to 100?

How does a digital retrofit for legacy systems work in concrete terms? How long does it take?

Can companies really react promptly and adequately?

LeanBI answers these and other exciting questions in the interview with dispo.cc.

dispo.cc Mit einem digitalen Retrofit können Unternehmen eine Anlage noch Jahrzehnte betreiben

LeanBI in the media on the topic:

Easily monitor machines and systems while minimizing faults and downtimes? Thanks to the partnership with GradeSens, even more precise evaluations and forecasts are now possible, which further reduce machine and system failures. Read more about how exactly our AI-based data analysis optimizes GradeSens’ predictive maintenance solution in the following specialist media.

Industry-Channel: Predictive Maintenance auf neuem Level

ITIKO IT und Kommunikations-News: LeanBI und GradeSens heben Predictive Maintenance auf ein neues Level

Betriebstechnik & Instandhaltung: Predictive Maintenance auf neuem Level

Industr.com: Wie KI-Datenanalysen Predictive Maintenance erleichtern

bigdata-insider.de: LeanBI und GradeSens optimieren Predictive Maintenance

Produktionsleiter.today LeanBI und GradeSens heben Predictive Maintenance auf ein neues Level

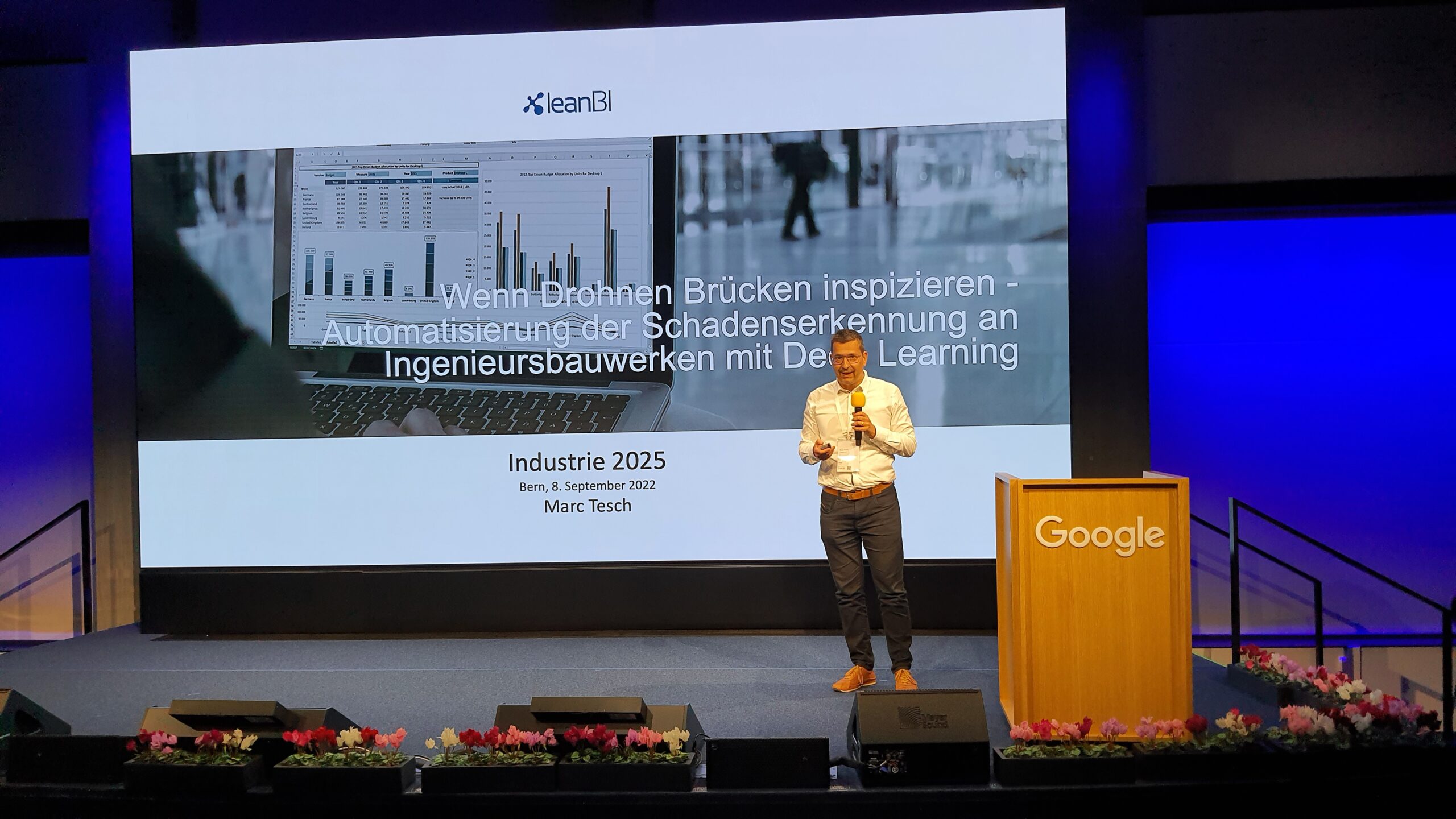

Postcard from the Industry 4.0 Use Cases event at Google in Zurich

Picture: Marc Tesch during the presentation

That was an exciting day! Marc Tesch presented a use case at Google in Zurich as part of the 3rd Industrie 4.0 Use Cases.

LeanBI in the media on the topic:

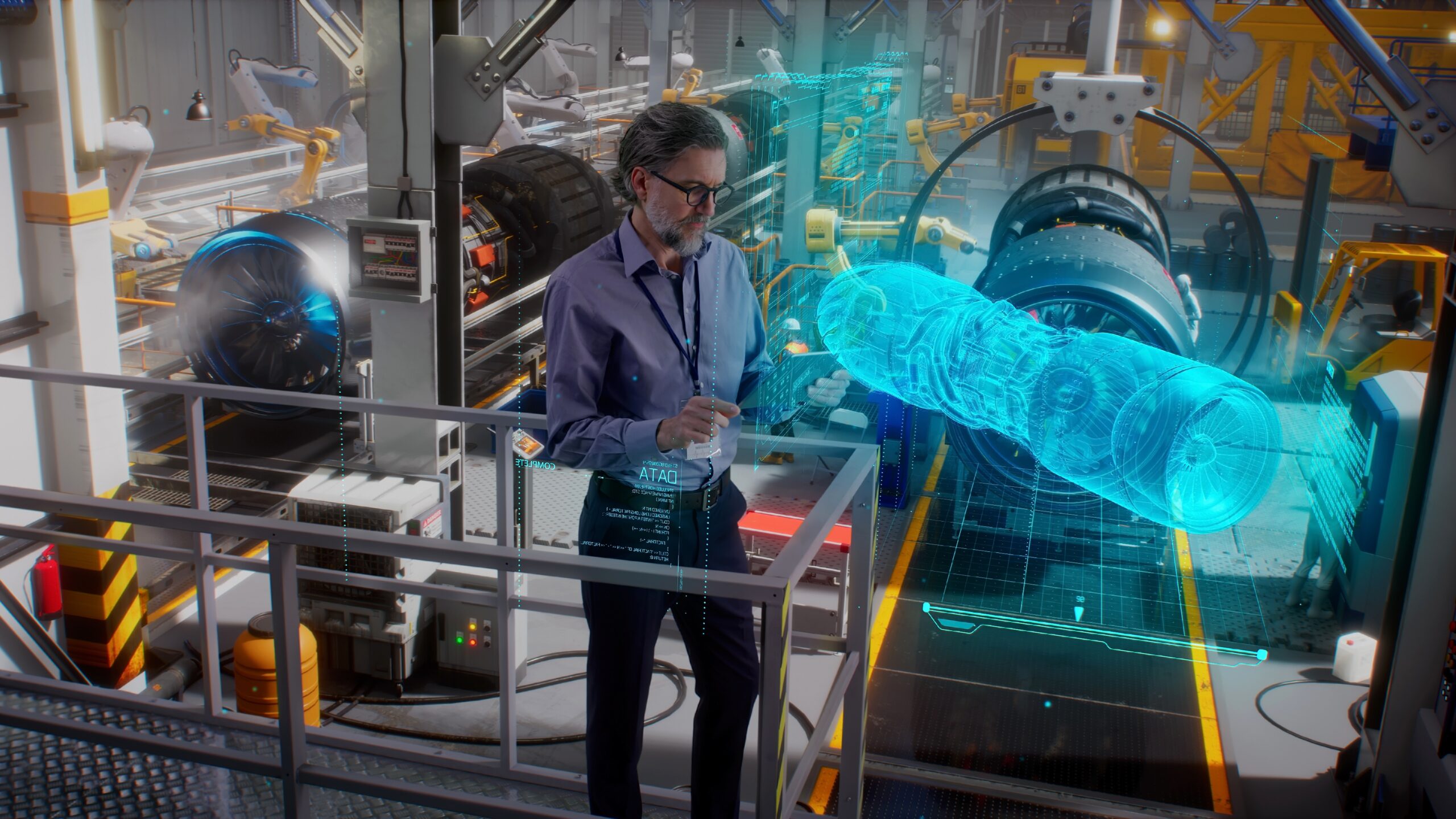

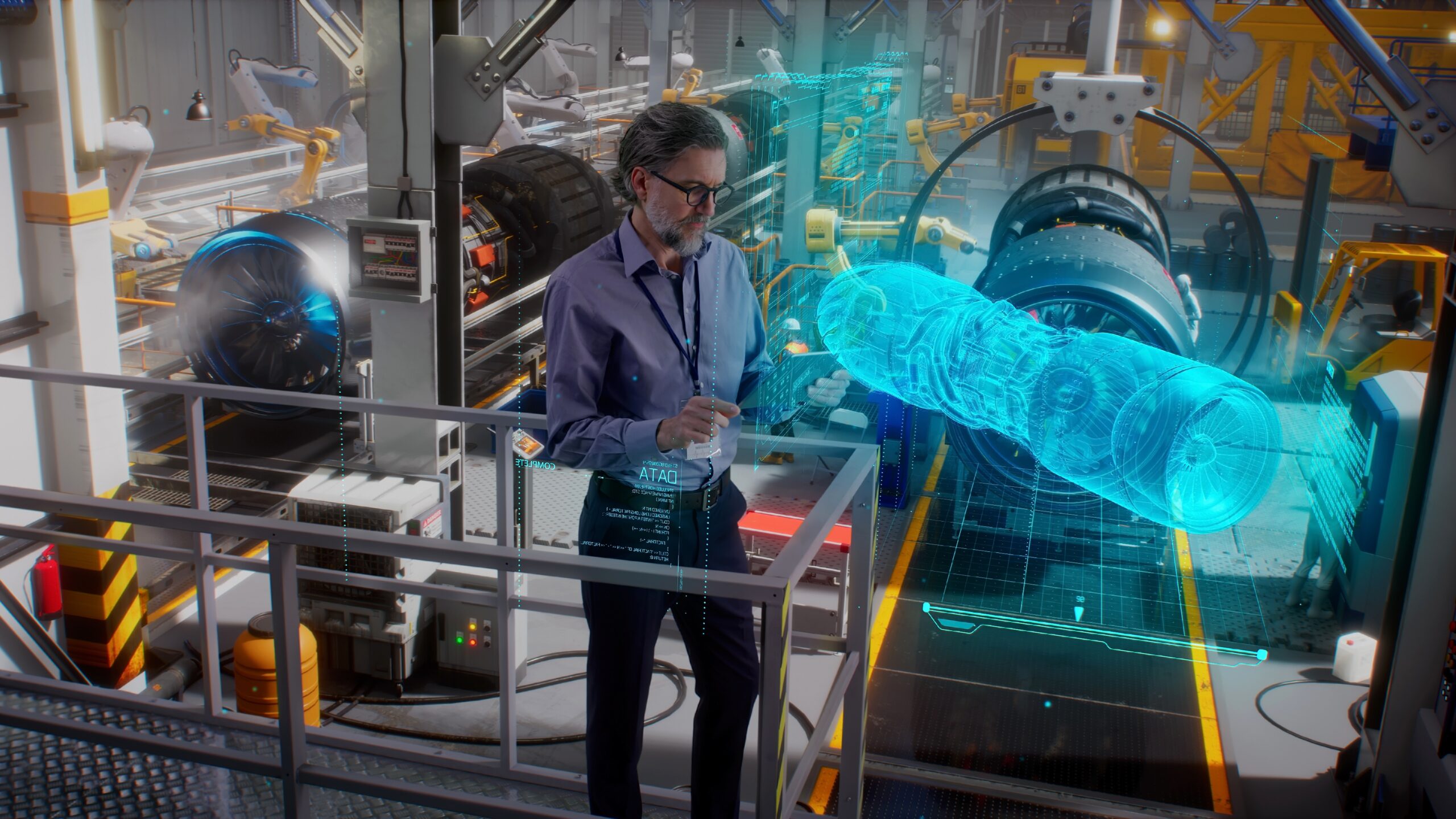

AI and physical models simplify and accelerate the development of complex products and processes. This can be clearly seen in five typical application scenarios. These include production planning, predictive maintenance of components and damage detection of components. We have described in detail in the article how this works and what other use cases are involved.

www.industry-of-things.de: Welches Potenzial hat die Kombination von KI und physikalischen Modellen?

IT-daily.net: Die Kombination von KI und physikalischen Modellen eröffnet neue Optimierungspotenziale

www.bigdata-insider.de: Wie KI und physikalische Modelle Optimierungspotenziale eröffnen

https://de.eas-mag.digital: Die Kombination von KI und physikalischen Modellen eröffnet neue Optimierungspotenziale

www.itiko.de: Die Kombination von KI und physikalischen Modellen eröffnet neue Optimierungspotenziale

www.iavcworld.de: Praktische Szenarien zur Anwendung von KI und ML

Half-day seminar «Digital Retrofit 4.0» – How to make your plant fit for the digital future

The experts LeanBI, SICK, Brütsch & Rüegger and GradeSens will work out the positive effects of digital retrofits with you in an interactive dialogue in several small groups.

Industrie 2025, Swissmem and the Data Innovation alliance cordially invite you. The seminar will take place at Swissmem in Zurich on 24.11.2022 from 13:00 – 17:30, starting at 17:30 apero and closing.

Program and registration

LeanBI in the media on the topic:

Quality is one of the most important factors in production. For this reason, many companies rely on predictive quality applications that permanently optimize the quality of products and processes. Often, this is done via the cloud, but especially when things have to move quickly, it pays to rely on edge computing. We show what companies need to pay attention to and how they can optimize machine learning models so that they can be used on edge systems.

www.industry-of-things.de: Warum Edge Computing bei Predictive Quality oft die bessere Wahl ist

www.it-daily.net: Bei Predictive Quality ist Edge Computing oft die bessere Wahl

www.it-production.com: Predictive Quality: Was, wenn es schnell gehen muss

www.i40-magazin.de: Was, wenn es schnell gehen muss?

www.service-and-maintenance.com: Predictive Quality: Was, wenn es schnell gehen muss

www.itiko.de: Bei Predictive Quality ist Edge Computing oft die bessere Wahl

www.iavcworld.de: Bei Predictive Quality ist Edge Computing oft die bessere Wahl

LeanBI in the media on the topic:

Not only since Corona have companies and organizations been concerned about the air quality in rooms. Only when the air quality is right can employees be efficient, energy costs optimized and office and conference rooms optimally utilized. But how can air quality actually be measured? We show what positive effects can be achieved.

Management und Qualität: Indoor air quality: Five reasons for more transparency

Organisator: Indoor air quality: Five reasons for more transparency

www.maschinenmarkt.de: Fünf gute Gründe für eine smarte Sicherung der Luftqualität

LeanBI in the media on the topic:

Detecting damage to infrastructures such as bridges, tunnels or canals in the conventional way is time-consuming, expensive and even dangerous. When experts inspect bridges or tunnels on site, they have to be closed off. Inspectors can only get to bridges with lifting platforms or by abseiling, which entails a risk to life and limb.

bigdata-insider.de: Whether bridges, tunnels or canals: Data analytics solutions can automate infrastructure damage detection.