See how drones, artificial intelligence and risk engineering are helping inspectors.

Automated analysis based on recorded data from optical sensors improves the speed, accuracy and consistency in the detection and assessment of wear and damage.

See how drones, artificial intelligence and risk engineering are helping inspectors.

Automated analysis based on recorded data from optical sensors improves the speed, accuracy and consistency in the detection and assessment of wear and damage.

Monday, 30.8.2021, 18:00 –22:00

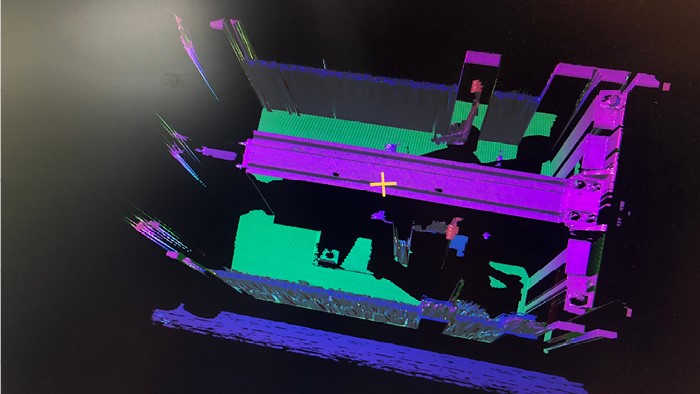

With suitable sensor technology, IoT and artificial intelligence, plants and machines can be monitored automatically. The smallest changes such as bends or breaks can be detected in the millimeter range. This technology was implemented at the Swiss Post parcel center in Härkingen.

LeanBI was able to successfully complete the go-live at the Swiss Post sorting facility. Marc Tesch reports at the AI Use Case Talk how a complex predictive maintenance project starting with a POC over a pilot finally can be transferred into a productive solution.

Here is the link to the agenda: AI Use-Case Talk Series 2021

Monday, 14. June 2021, 18:00 –22:00

With suitable sensor technology, IoT and artificial intelligence, plants and machines can be monitored automatically. The smallest changes such as bends or breaks can be detected in the millimeter range. This technology was implemented at the Swiss Post parcel center in Härkingen.

LeanBI was able to successfully complete the go-live at the Swiss Post sorting facility. Marc Tesch reports at the AI Use Case Talk how a complex predictive maintenance project starting with a POC over a pilot finally can be transferred into a productive solution.

Here is the link to the agenda.

Please read also our last blog: Die Post setzt auf Predictive Maintenance zur Überwachung der Sortieranlage mit AI der LeanBI