Industry 4.0 means in concrete terms: Connect machines, industrial goods and the tasks of employees using the latest sensor, internet and data science technology. We are engineers who digitalize with IoT and data science your production and logistics. We create for you the digital twins of your machines, plants, and factories.

Industry 4.0 makes you not only more efficient and leaner, but also enables you to apply new business models and provide new digital services for your customers. Starting from automating material orders, energy savings in production, improved production planning, efficiency dashboards, predictive maintenance, you arrive to full-fleshed Product as a Service.

With Industry 4.0 manufacturing companies integrate their plant engineering with production and maintenance to create a central database covering all areas: On the way to a Smart Factory.

The potential of data is often insufficiently used in the factory, even if manufacturers are constantly optimizing their processes and production.

We help to optimize quality control, be it to reduce control steps or to systematize and automate manual controls with Machine Learning and Data Science.

Machine Learning can also be used to automate adjustment processes in production and to combine sensor data in such a way that expensive measuring systems become obsolete. This is what we then call virtual sensors. At the end of the road is the Smart Factory.

At LeanBI, we have implemented successful projects on different Smart Factory topics that let us gain the experience we need to support you in your endeavor.

The networking of logistics and production with a central Data Lake brings great added value even without data analysis and data science. In this way you create the basis for a digital twin.

This means you always know the condition of the components in your process. Energy and material consumption is under continuous control and can be continuously optimized.

The performance of the systems is subject to a benchmark across the factories and logistics processes. Failures are immediately visible, you receive warnings and later these data can be processed analytically.

And the data flows directly into the engineering for the optimization of the plants and new developments.

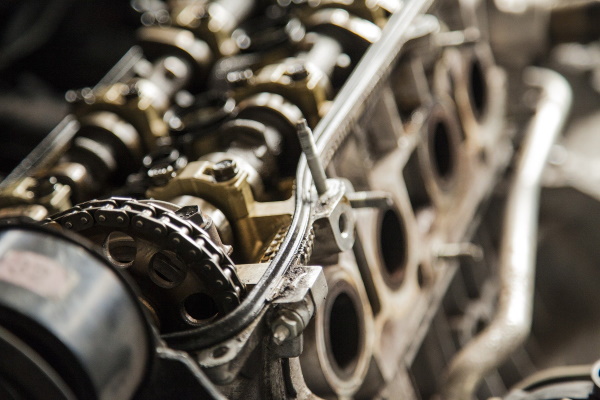

We offer Plug & Play Predictive Maintenance up to individualized PdM solutions for your company.

Maintenance schedules are often static and not very well adapted to the individual process components. Usually a predefined plan determines when the next maintenance takes place.

This seems to be sufficient for many companies. However, they overlook the fact that maintenance could also be optimized. Those who have in-depth knowledge of the parts to be maintained can not only save costs, but also reduce downtimes and thus achieve more constant operating conditions.

Predictive maintenance therefore minimizes expensive downtimes, saves costs and, last but not least, increases product quality. It is therefore a key success factor for your company.

Digitalization offers many opportunities, but it also creates a new field to compete. This also applies to SMEs: In order to remain competitive in the long term, they too should always be on the ball.

A future-oriented option to keep up is to do more than just sell products. Products are today supplemented with their own services or are even offered as independent services. This is what we call Product as a Service (PaaS).

When offering services it is necessary to collect intensive measurement data on the product. This ensures constant information about the operating conditions, but also the opportunity to service the products in time and monitor whether the service level agreements are being met.

At LeanBI we help you develop new business models and then implement them, so that you always stay future-proof.